The Evolution and Future of Beverage Packaging Equipment

Apr 09, 2025

The beverage industry has come a long way since its inception, and so has the equipment that supports it. KOCO IMP/EXP CO., LTD has been at the forefront of beverage manufacturing for 25 years, leveraging our expertise to deliver high-quality products. As the industry evolves, so do we—embracing advancements in filling technology to meet the growing demand for efficient and sustainable beverage production.

Key Features of Modern Beverage Equipment

Today’s beverage equipment is designed for speed, precision, and versatility. Here’s what makes modern machines different:

High-speed operation: These machines are capable of processing thousands of packages per hour, maximizing productivity.

Precision filling: Ensures consistent product quality by accurately measuring and filling liquids.

Sanitary design: Stainless steel construction and easy-to-clean components ensure compliance with food safety standards.

Versatile use: Can accommodate a variety of packaging formats, including bottles, pouches, and cartons, ideal for a wide range of beverage types.

ketchup packing machine

For the production of spout pouch liquid packaging.

koyo sachet machine

Used in sachet liquid packaging production.

pouch packing machine

Used for pouch liquid packaging production.

ross-industry applications

Beverage packaging equipment is not limited to juice and soda. It is versatile and can be used for:

Beverage manufacturing: Ideal for juices, tea drinks, dairy products, and more.

Food Industry: For sauces, condiments, and other liquid products.

hemical Industry: Dishwashing liquids, laundry detergents, cleaners, etc.

Health-conscious market: Meeting the demand for fresh, organic, and nutritious beverages.

doypack

For packaging juice, yogurt, jelly, laundry detergent, etc.

PE Plastic Film Roll Bag

For packaging Sachet Water/Juice/Milk, etc.

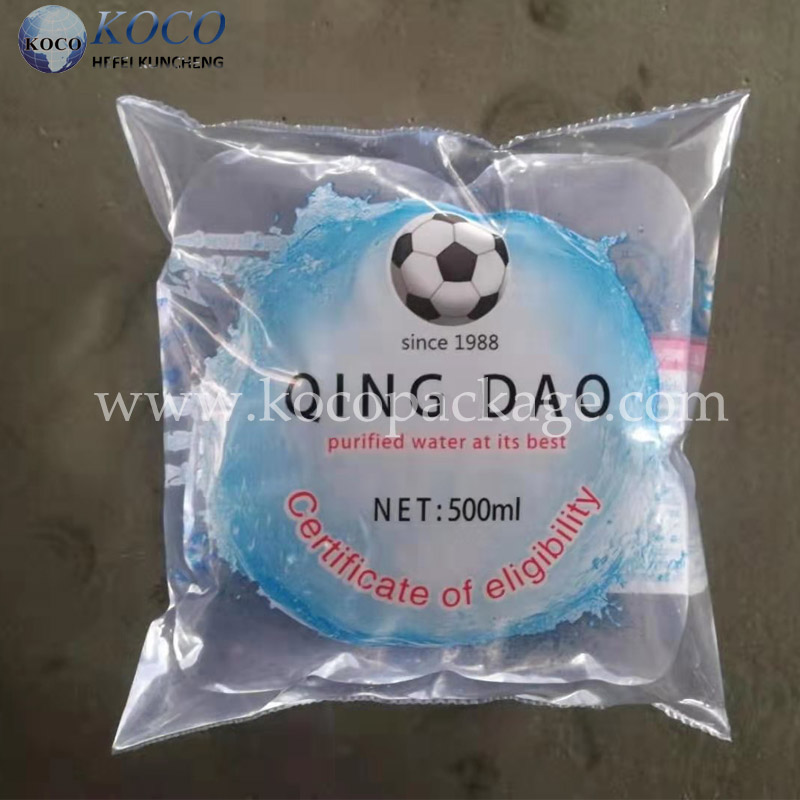

Special-Shaped Bags

For packaging juice, water, milk and other liquids.

Market Outlook and Trends

The market for automated beverage packaging solutions is booming, driven by consumer preferences for convenience and health. Here are the factors shaping the future:

Large-scale production: Equipment is trending toward larger capacities to optimize costs and meet large-scale production needs.

Smart technology integration: Modern machines feature IoT connectivity, real-time data monitoring, and AI-driven customization.

Sustainability focus: Innovations in eco-friendly packaging and energy-efficient operations are gaining traction.

Our Latest Innovations

At KOCO, we are committed to pushing boundaries. Our latest equipment combines advanced automation with a user-friendly interface to simplify operations while increasing efficiency. Whether you need a stand-alone juice packaging machine or complete juice treatment equipment, our team of experts will work with you to design the perfect solution for your business.

Conclusion

The beverage industry is rapidly evolving, and so is the technology that drives it. By investing in modern, versatile equipment, businesses can stay ahead of the curve while meeting consumer demands for quality and sustainability. Are you ready to change your beverage production? Let's build the future together!

Contact number: 0086-19159001917