High speed emulsification mixing tank

High-speed emulsification mixing tank are usually used to produce juice, yogurt and other liquid beverages. It has high-speed shear stirring and heating and heat preservation functions.

MODEL :

KOCOPOWER :

38kwVOLTAGE :

220v 380vWEIGHT :

150kgSIZE :

1200xz1200x1800mmVOLUME :

1000LHigh speed emulsification mixing tank

Machine Features:

High speed emulsification mixing tank usually consists of a container and corresponding stirring mechanism. It is mainly used to mix and stir various food additives under high temperature conditions to achieve uniform fusion of various additives.

Machine advantage:

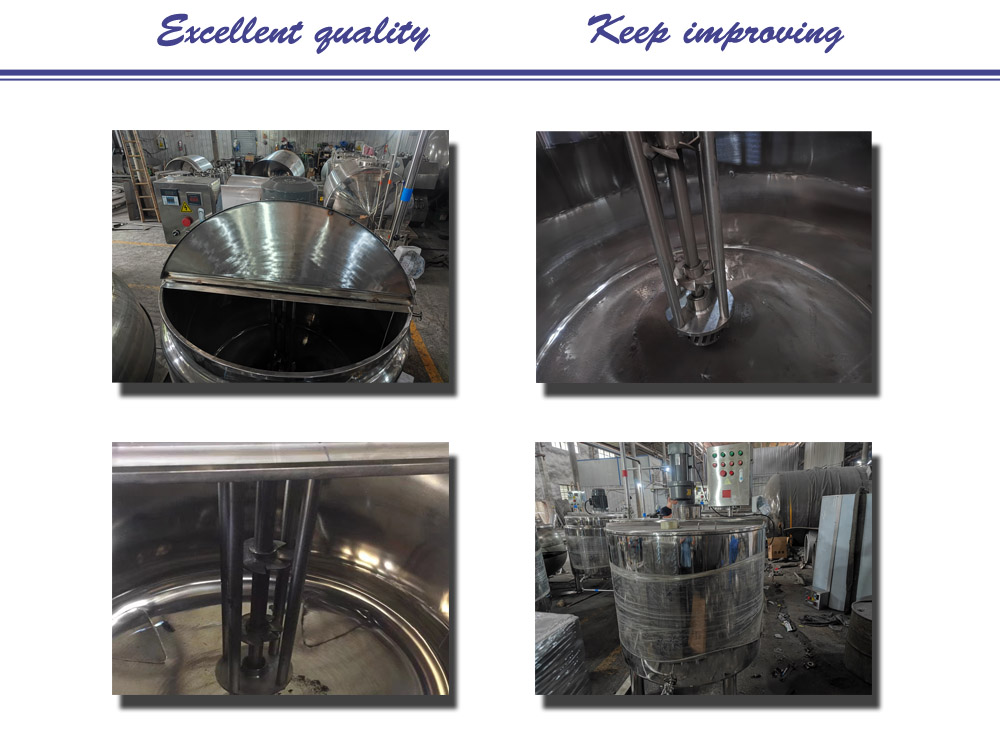

The High speed emulsification mixing tank is usually made of high temperature resistant materials, such as stainless steel. The container has the characteristics of high temperature resistance and corrosion resistance, and can withstand the pressure and temperature during high temperature shearing. The equipment is equipped with a stirring mechanism, which generally consists of a motor, stirring blades and transmission device. The operator can control the start and stop of the stirring mechanism, speed adjustment, etc. through the control panel or buttons. The equipment is usually equipped with a temperature control system to control and maintain the temperature inside the mixing tank. The temperature control system can be set according to processing requirements and monitor and adjust the temperature inside the mixing tank.

easy to use:

Semi-automatic high-temperature shear tank require the operator to perform some manual operations, such as adding raw materials, controlling stirring, adjusting temperature, etc. Operators need to operate according to processing requirements and ensure safety and production results.

Machine Precautions:

High-temperature shear tank are mainly suitable for small and medium-sized production scenarios. Its operation is relatively simple and flexible, and it is suitable for some processes that do not require high production efficiency but require high-temperature shearing treatment. When choosing, you need to consider factors such as the equipment's capacity, mixing effect, temperature control capabilities, and ease of operation. It is best to communicate and understand in detail with the supplier to choose equipment that suits your needs. Specific features and specifications of equipment may vary by manufacturer and application area.

After-sales service:

The whole machine is guaranteed for one year, and the core components are guaranteed for two years.

Can provide engineers to go abroad to install services.

Beverage production lines and factory layouts can be designed according to customer requirements.

Long-term supply of machine parts and packaging materials.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.