fully automatic bottle blowing machine

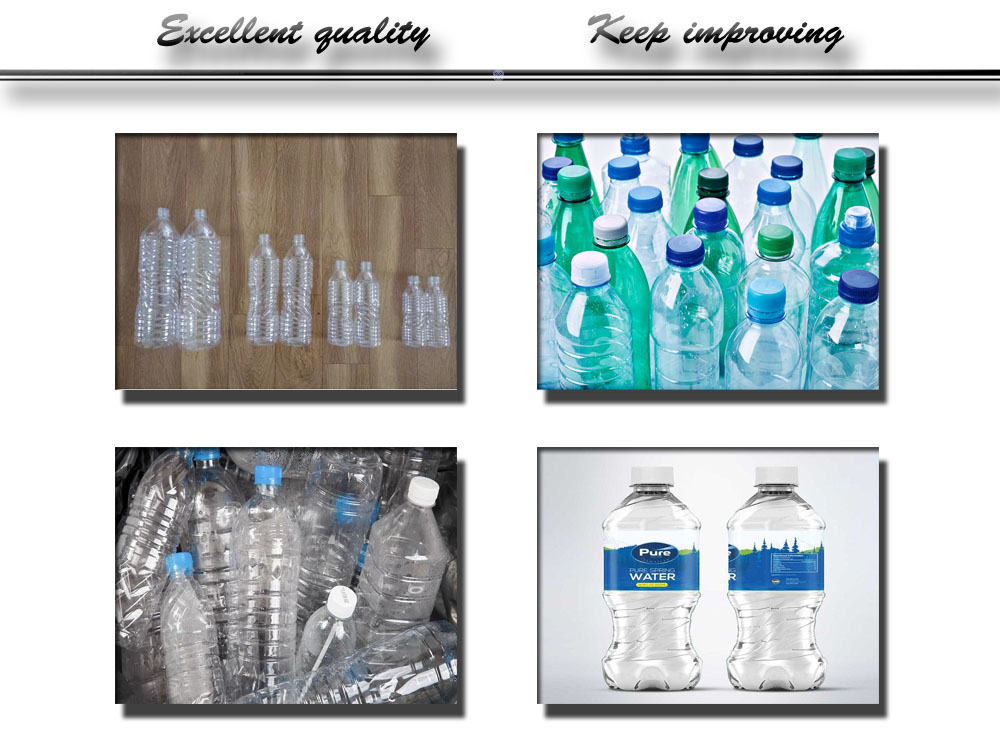

The fully automatic bottle blowing machine is an important equipment for the production of beverage bottles, especially in the production of PET bottles. It can efficiently and accurately produce beverage bottles of various specifications and shapes, such as mineral water bottles, carbonated beverage bottles, juice bottles, tea beverage bottles, energy drink bottles, etc., to meet the needs of large-scale production.

Productive capacity :

2500-3000Pcs / hWeight :

2200kgSize :

2700×1700×1800mmVoltage :

380V50HZNumber of mold cavities :

2cavitiesClamping Force :

200knBlowing pressure :

≤35kg/c㎡Maximum heating power :

32kwMaximum capacity of bottle :

1.5LStretching Stroke :

450mmTotal power of machine installation :

32kwMaximum outer diameter of bottle mouth :

18-38mmWorking Pressure :

7kg/c㎡Actual power consumption :

20kwMaximum diameter of bottle body :

105mmBottom mold stroke :

30mmLow pressure gas consumption :

1200Ltr/minMaximum height of bottle :

330mmCavity spacing :

115mmMould Stroke :

140mmHigh-pressure gas consumption :

2000-2500Ltr/minNumber of lamp tubes :

32pcsFully automatic blow molding machine

The fully automatic bottle blowing machine is an important equipment for the production of beverage bottles, especially in the production of PET bottles. It can efficiently and accurately produce beverage bottles of various specifications and shapes, such as mineral water bottles, carbonated beverage bottles, juice bottles, tea beverage bottles, energy drink bottles, etc., to meet the needs of large-scale production.

Machine structure:

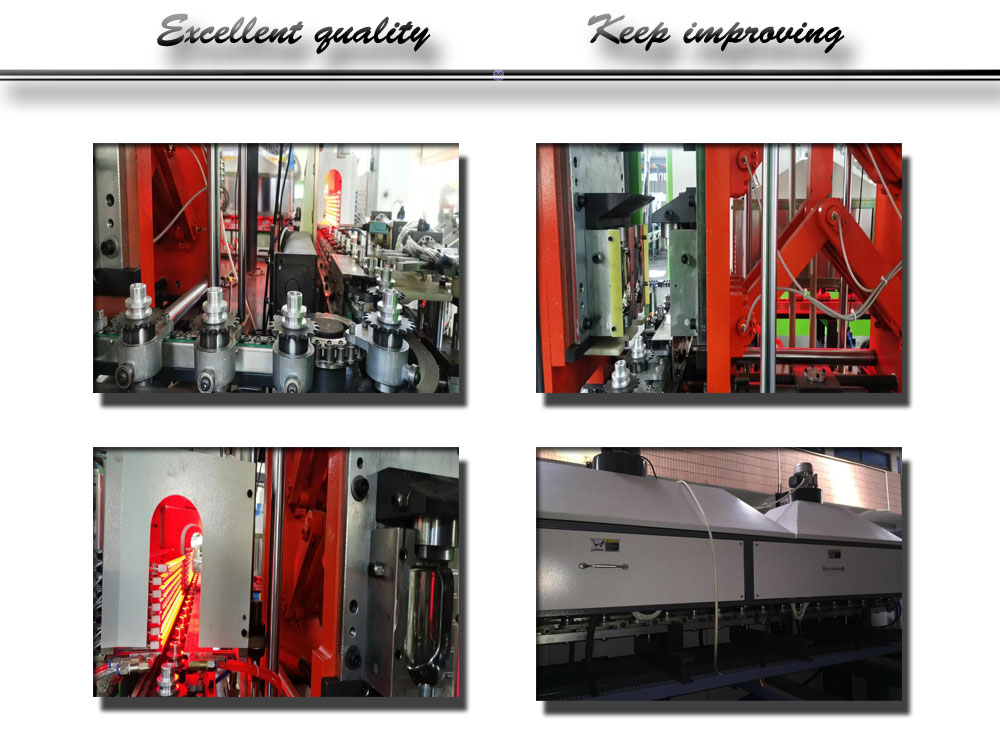

The Automated Plastic Bottle Shaping Machine mainly consists of the following parts:

Bottle feeding device: responsible for feeding the preforms into the heating zone to ensure that the preforms can be accurately and quickly positioned.

Heating device: Use infrared or hot air to preheat the preforms to make them soft and easy to blow mold.

Mold device: The shape and size of the mold determine the final appearance of the bottle. The mold usually consists of two parts, upper and lower.

Blowing device: Compressed air is injected into the mold through an air compressor, an air tank and a blow valve to shape the preforms.

Removal device: Remove the molded bottle from the mold and transfer it to the next link.

Control system: As the "brain" of the machine, it is responsible for coordinating the work of various components to achieve automated production.

In addition, the fully automatic bottle blowing machine also realizes fully automated production from raw material heating to finished product output. And it adopts efficient heating technology and rapid cooling function to reduce energy consumption. Through precise mold design and automatic adjustment function, product quality is ensured. These characteristics make the Fully Automated Bottle Making Equipment have important application value in the modern packaging industry.

FAQ

Q1: What is your installation service?

All new machines purchased can provide engineers with overseas installation services.

If you can install it yourself, we will provide user manual and video to support the installation, debugging, operation of the machine, it will guide you how to use this machine well.

Q2: How to get the wearing parts of the machine?

When we sell the machine, we can provide you with a list of parts for your reference and purchase. We can provide machine supporting parts for a long time.

Q3: Do you also provide matching package material?

Yes, we can provide you with packaging materials for the machine, and we have long-term cooperative packaging material suppliers with favorable prices.

Q4: How can I ship the machine to my country?

You can entrust us to transport the goods, and we can ship the goods to your country's port by sea.

Q5: Does the machine require professional engineers to operate?

unnecessary. The operation of this machine is very simple, just follow the instructions. We can also tell you how to operate the machine by video.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.