Pouch liquid packaging machine

Pouch liquid packaging machines are essential equipment in the packaging industry, used to pack liquid products into packaging bags and seal them. The machines are designed to handle a variety of liquids, including beverages, juices, dairy products, purified water, etc. They are known for their efficiency, accuracy, and ability to maintain the freshness and integrity of the packaged products.

Model :

XY-BFilm developed width(mm) :

320/240mmPacking capacity(ml) :

100-500mlProduction efficiency :

2100 bags/hourApplication voltage :

380 or 220VHorse power :

1.5kwMachine weight :

1.5kwOverall dimension :

750x690x1900mmPouch liquid packaging machine

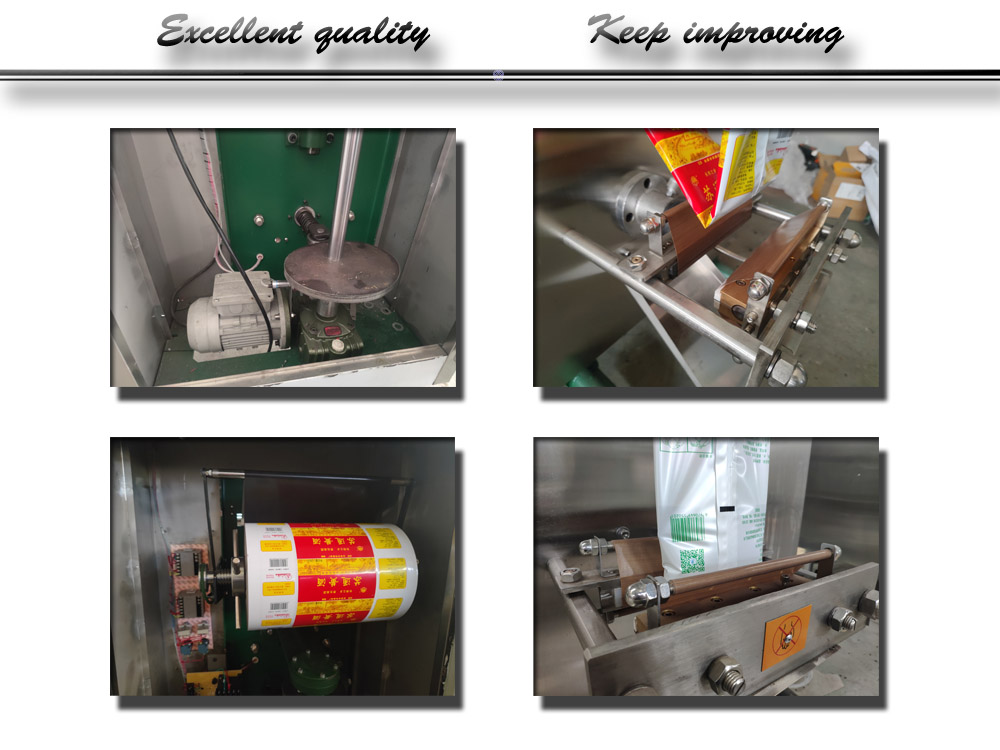

Machine introduction:

Pouch juice packaging machines operate on the form, fill and seal (FFS) principle. It first forms a bag with a roll of flexible packaging material, then fills the bag with the required liquid product, and finally seals it to ensure that the product is not contaminated and fresh. These machines are capable of high-speed production, up to around 2,100 bags per hour, depending on the specifications of the packaging and the products being packaged.

Machine Features:

One of the main features of these machines is flexibility. They can be adjusted to a variety of packaging speeds and bag lengths without manual intervention, allowing for efficient packaging of a variety of liquid products. These machines also offer multi-pass sealing capabilities, which can be three-side sealing or four-side sealing, providing options for different packaging designs and requirements.

In terms of materials, pouch juice filling machines can use a variety of packaging films, such as polyethylene, aluminum, and polypropylene, etc. These materials are usually heat-sealable composite materials that can provide a good barrier to oxygen and moisture, thereby maintaining the quality of liquid products.

Finished product display:

The machine is suitable for plastic film rolls of various sizes.

Machine advantage:

These machines are also designed with hygiene and safety in mind. They often include features such as stainless steel contact parts to ensure food safety and cleanability, as well as easy-to-clean designs to maintain high hygiene standards.

In summary, bag liquid packaging machines are sophisticated equipment that provide a high level of automation, precision, and flexibility in the packaging of liquid products. They are essential to maintaining product quality and efficiency in the food and beverage, pharmaceutical, and cosmetic industries.

FAQ

Q1: What is your installation service?

A1: All new machines purchased can provide engineers with overseas installation services. If you prefer to install it yourself, we will provide a user manual and video to support the installation, debugging, and operation of the machine. These resources will guide you on how to use the machine effectively.

Q2: How can I obtain the wearing parts of the machine?

A2: When you purchase the machine, we can provide you with a list of parts for your reference and purchase. We offer machine supporting parts for an extended period of time.

Q3: Do you also provide packaging materials for the machine?

A3: Yes, we can provide you with packaging materials for the machine. We have long-term partnerships with packaging material suppliers, ensuring favorable prices for our customers.

Q4: How can I ship the machine to my country?

A4: You can entrust us to handle the transportation of the goods. We can ship the machine to your country's port by sea.

Q5: Is it necessary to have professional engineers to operate the machine?

A5: No, it is unnecessary to have professional engineers to operate this machine. The operation is straightforward and can be easily understood by following the instructions. We can also provide instructional videos to guide you on how to operate machine effectively.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.