Introduction

The potato chip packaging machine is an efficient and intelligent packaging solution for a variety of products such as potato chips, peanuts and French fries. It is equipped with advanced features and technologies to ensure accurate, fast and reliable packaging.

Maintenance Tips

Regularly check and lubricate the moving parts of the machine to reduce friction and wear. Please follow the equipment manufacturer's recommendations on lubrication schedules and lubricant types.

Keep the machine clean and free of dust, debris and food residues. Clean the machine after each use to prevent the accumulation of contaminants that can affect packaging quality or damage components.

Regularly check the electrical system and wiring of the machine. Make sure all connections are secure and functioning properly to prevent electrical failures and ensure safe operation.

Monitor the performance of the machine during operation. Watch for signs of abnormal noise, vibration or inconsistent packaging, which may indicate potential problems that require maintenance or repair.

Arrange regular professional maintenance and servicing by qualified technicians to solve any potential problems and ensure the best performance and life of the machine.

Structural Description

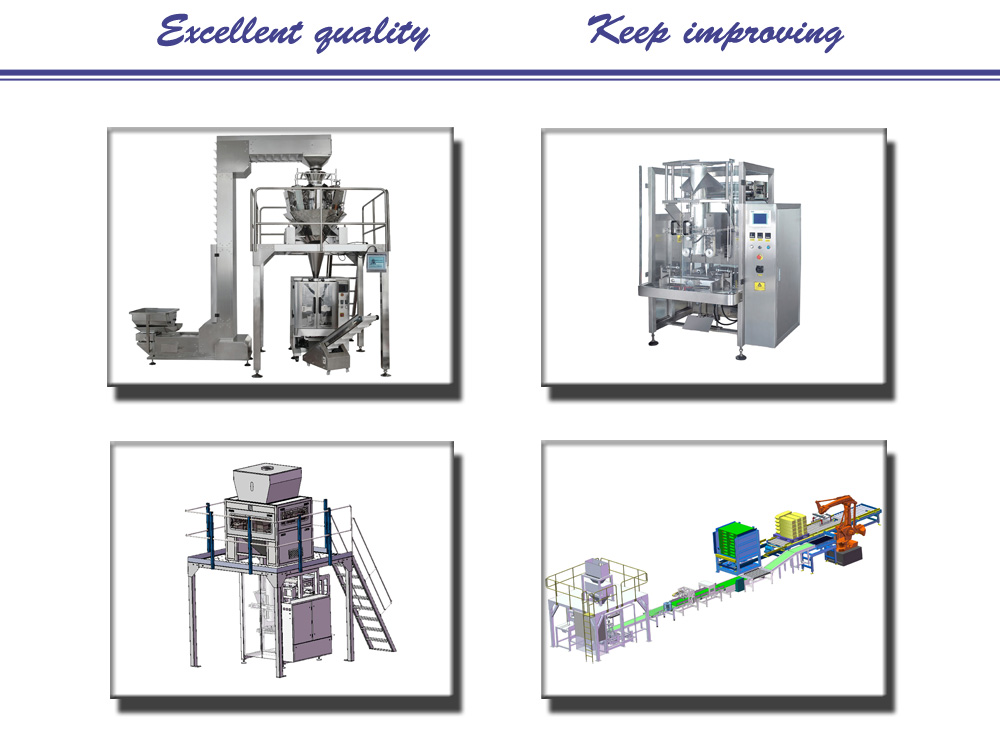

French fries packaging machines usually consist of several key components:

HMI (Human Machine Interface) and PLC (Programmable Logic Controller) systems: This is the control center of the machine, allowing the operator to easily program and monitor packaging parameters.

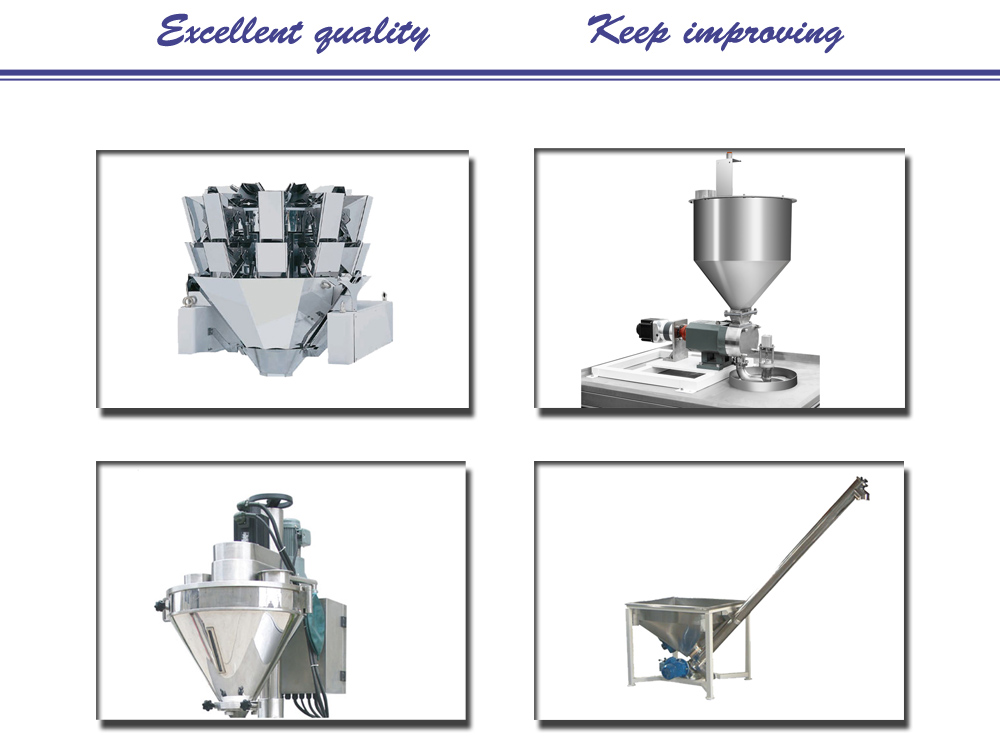

Feeding system: The machine is equipped with a volumetric feeder or weigher (such as a multi-head weigher) to accurately measure and feed the required amount of product into the packaging bag. The feeding system ensures a steady product flow and accurate dosage.

Packaging system: The machine is equipped with a film feeding and forming mechanism, a sealing system, and a cutting device. The film is fed through the machine, formed into bags, sealed, and then cut into individual packages. The sealing system uses heat to form a strong, leak-proof seal on the packaging material.

Conveyor system: The conveyor belt delivers the packaged product out of the packaging area, thereby facilitating smooth integration into the production line.

Material introduction

The granule packaging machine is made of high-quality materials to ensure durability, reliability, and food safety:

Stainless steel: Most parts of the machine, including the frame, contact parts, and sealing surfaces, are made of stainless steel. Stainless steel has excellent corrosion resistance, is easy to clean, and meets food safety standards. It ensures that the machine can withstand the harsh industrial environment and maintain hygiene during operation.

Food-grade plastics: Some parts of the machine, such as packaging film rolls and certain seals, may be made of food-grade plastic materials. These plastics are non-toxic, chemically and moisture-resistant, and suitable for direct contact with food.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.